The technical prototype bags I have designed represent the culmination of hands-on craftsmanship combined with cutting-edge innovation and thoughtful design principles. Each piece is meticulously constructed by hand in my studio, embodying a deliberately rigorous personal practice that seamlessly bridges the gap between traditional artisan skills and advanced technological processes. These bags incorporate the latest advancements applicable to softgoods, encompassing not only novel materials and manufacturing techniques but also groundbreaking functional applications that elevate everyday usability and style.

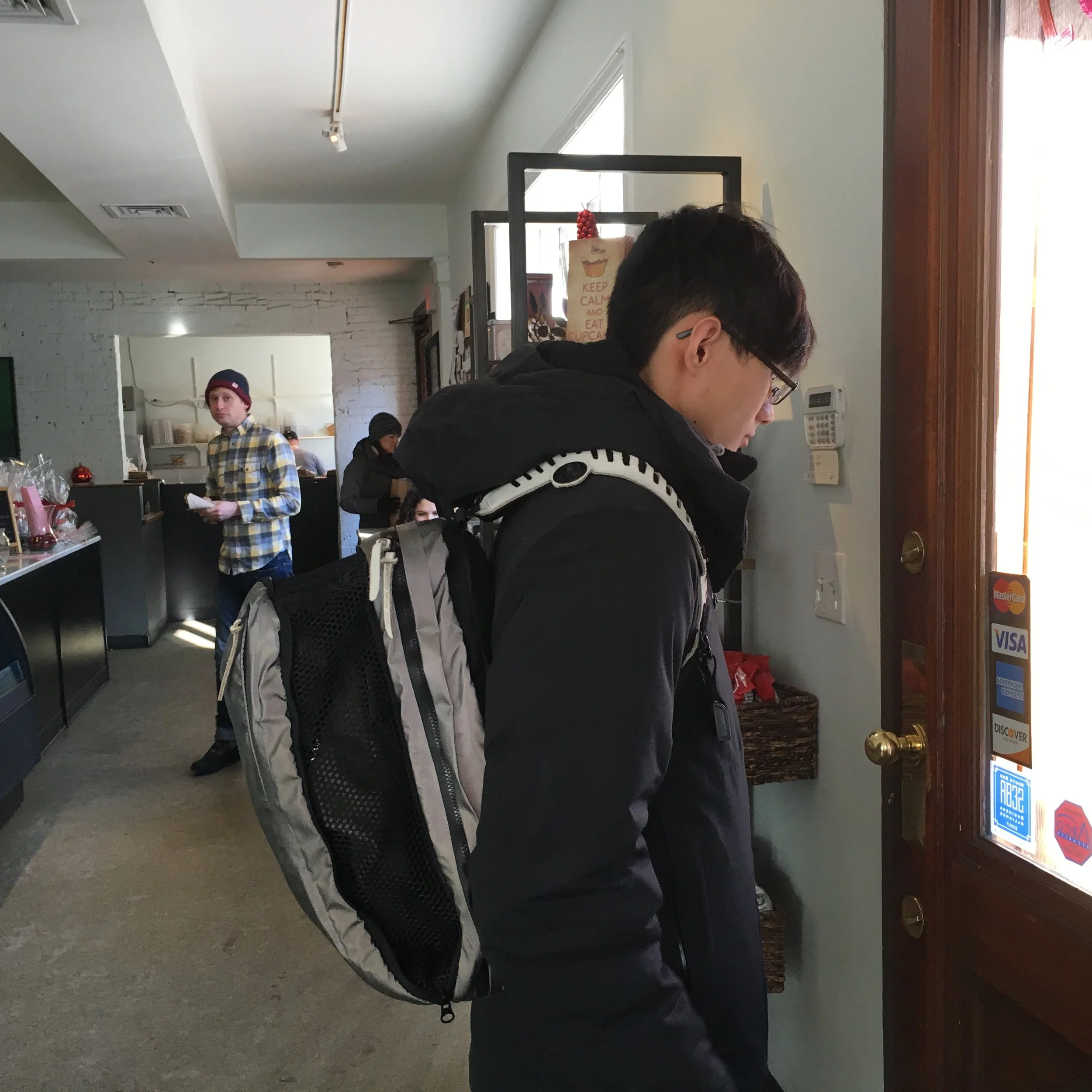

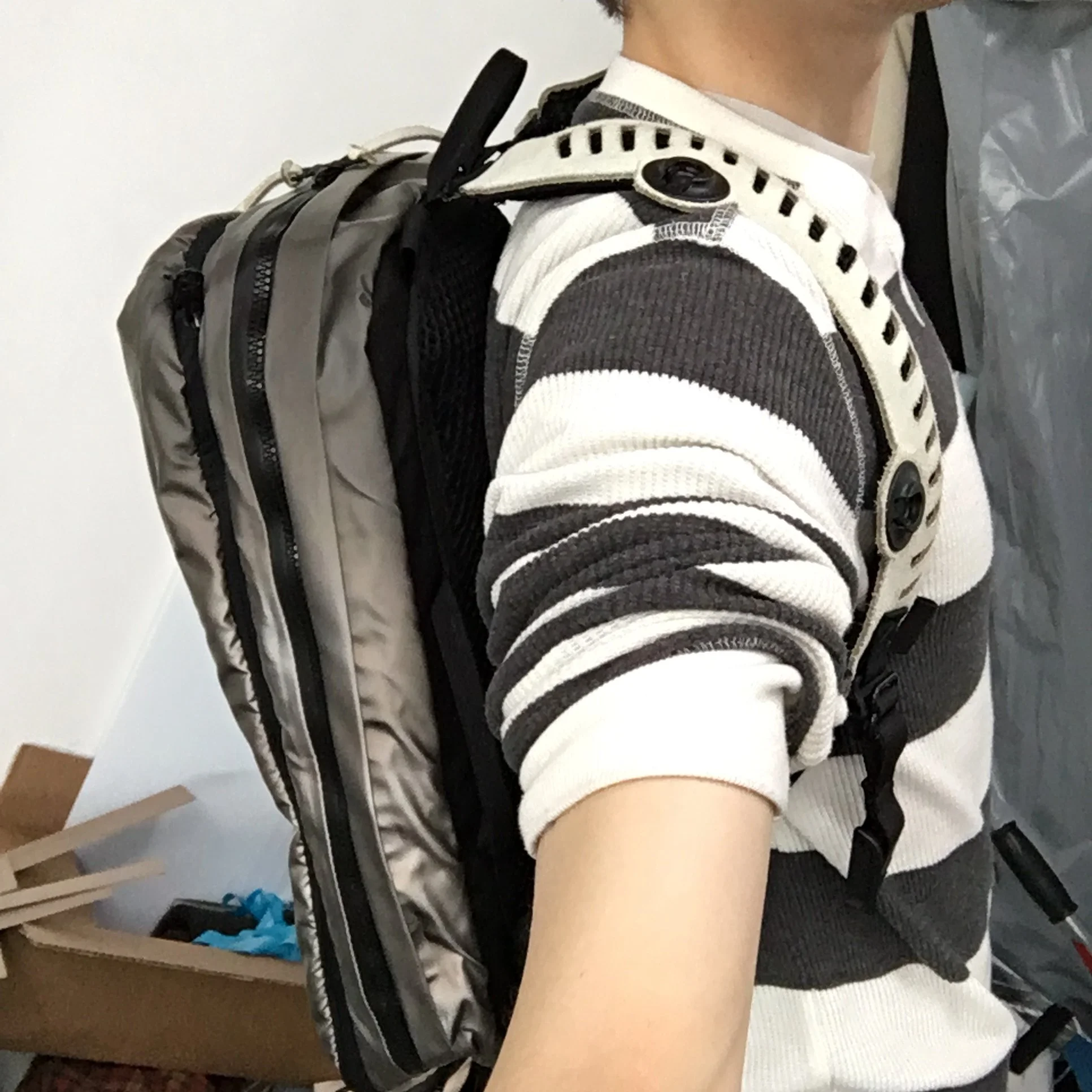

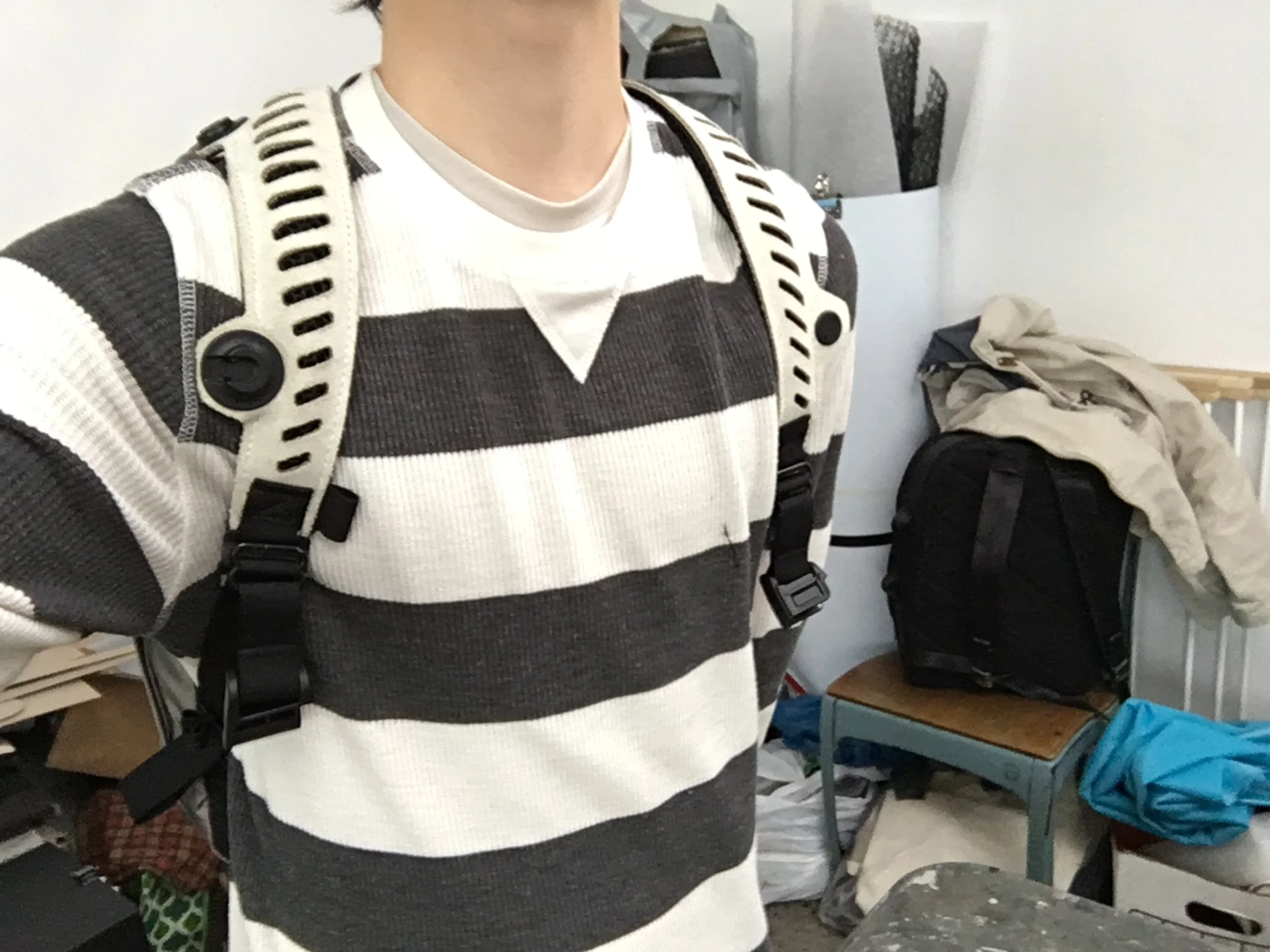

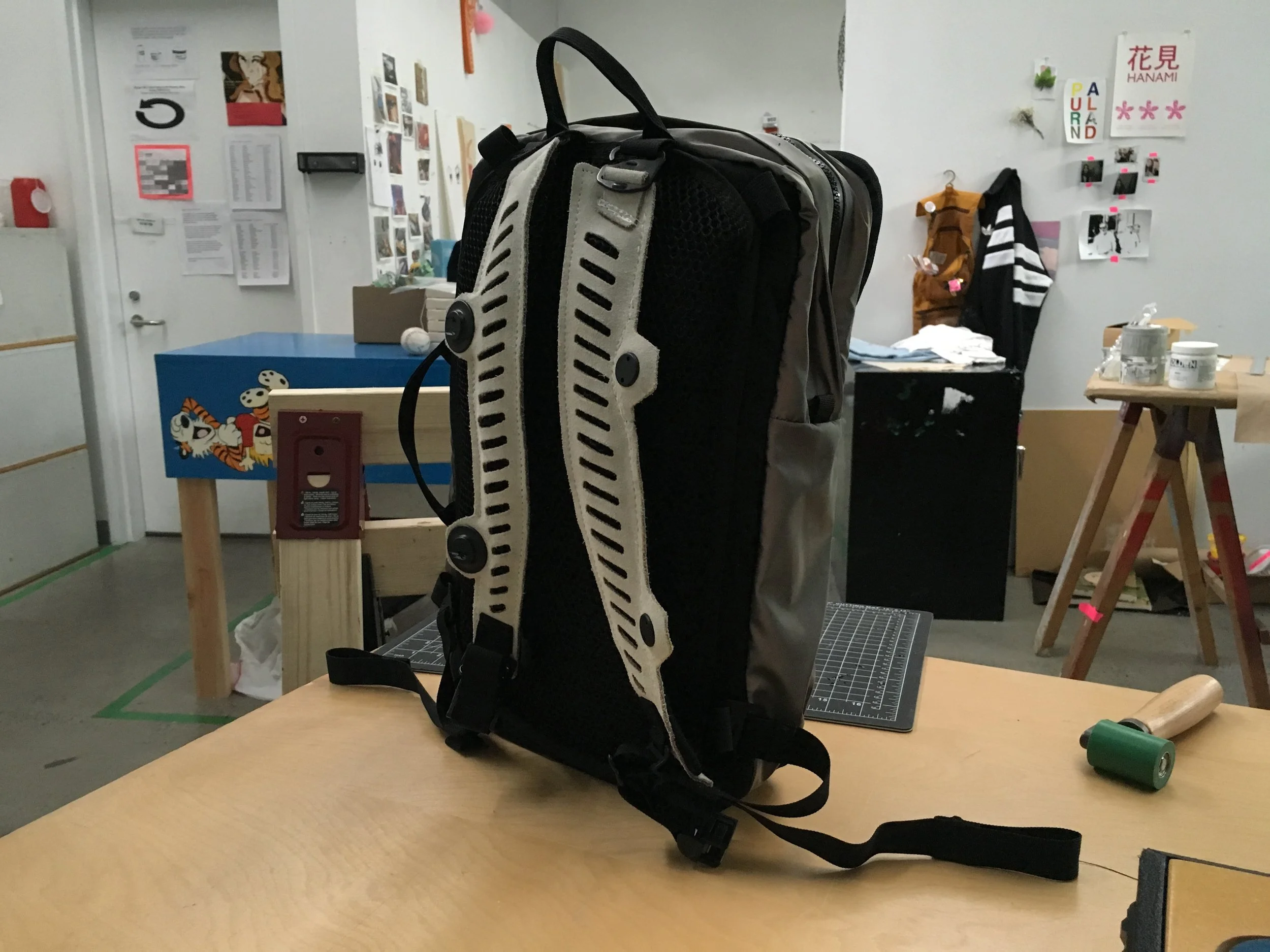

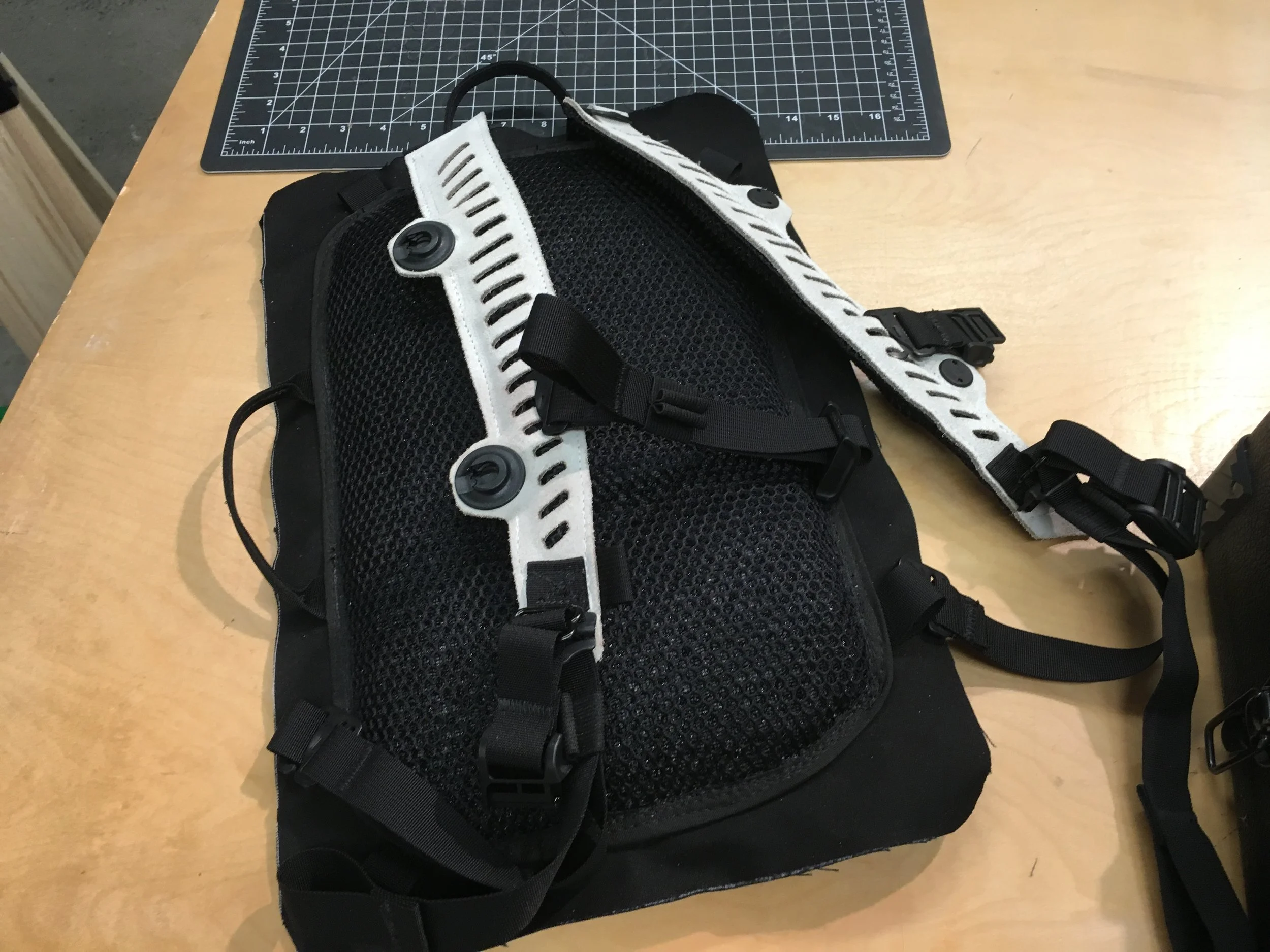

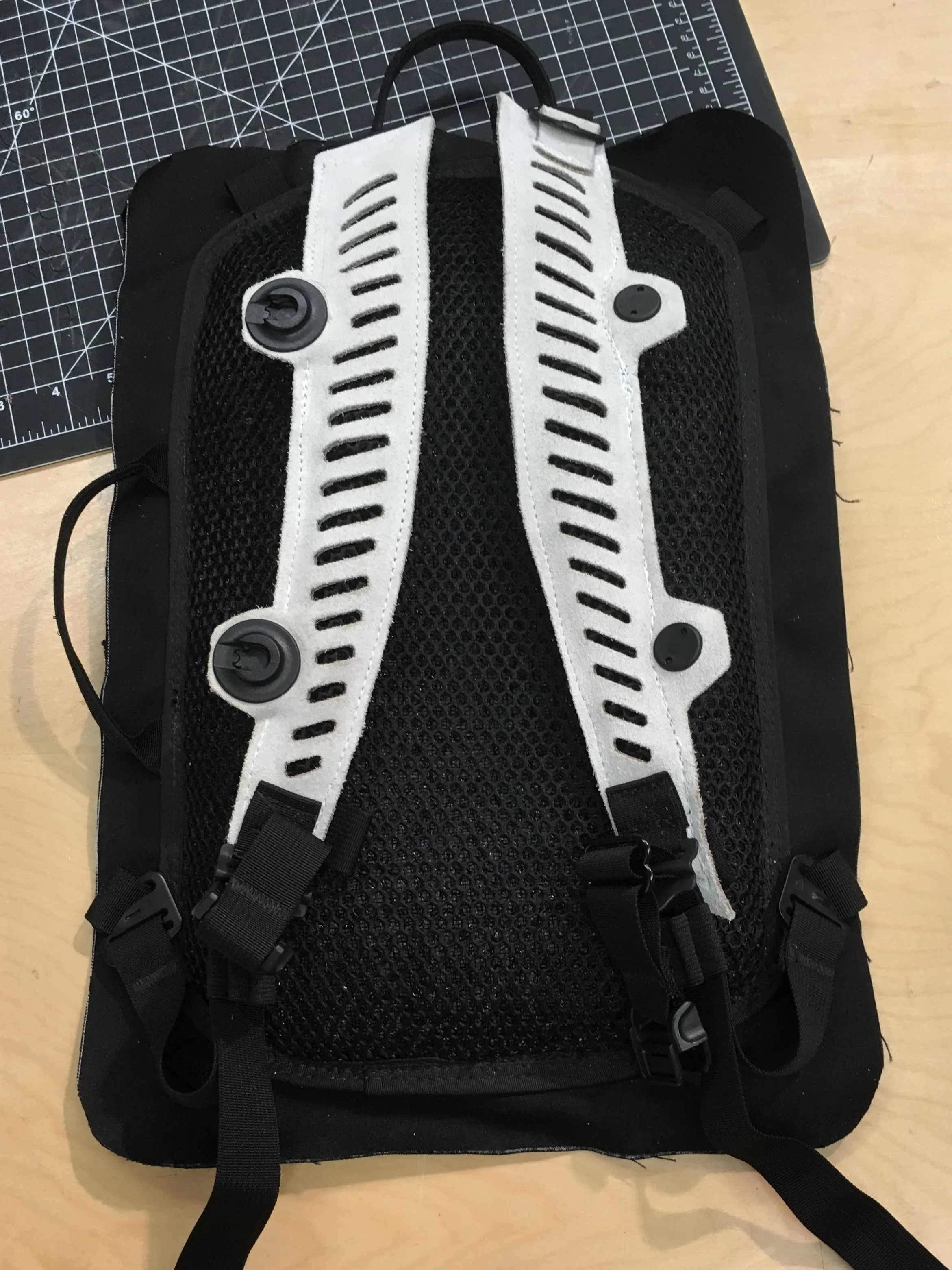

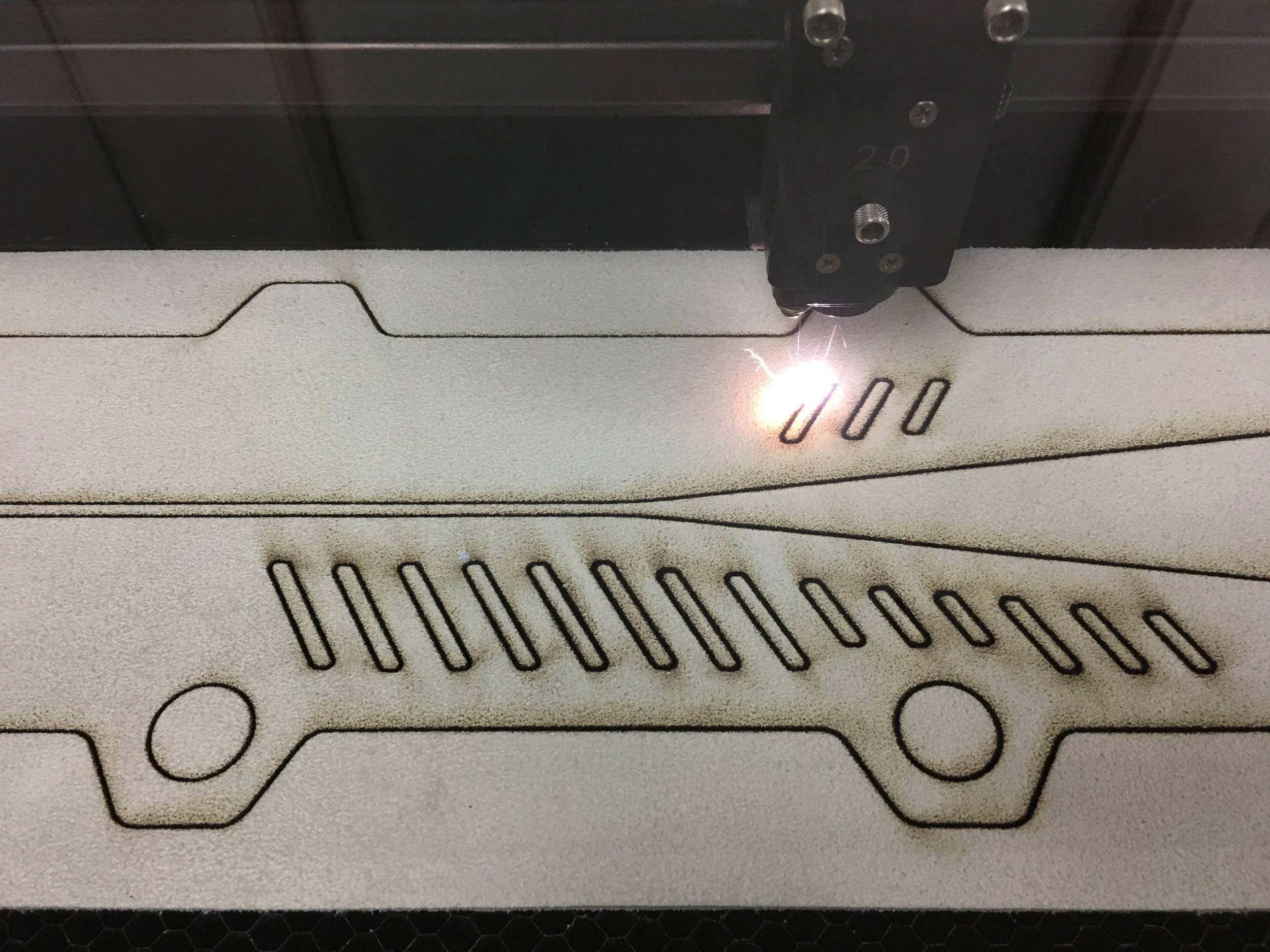

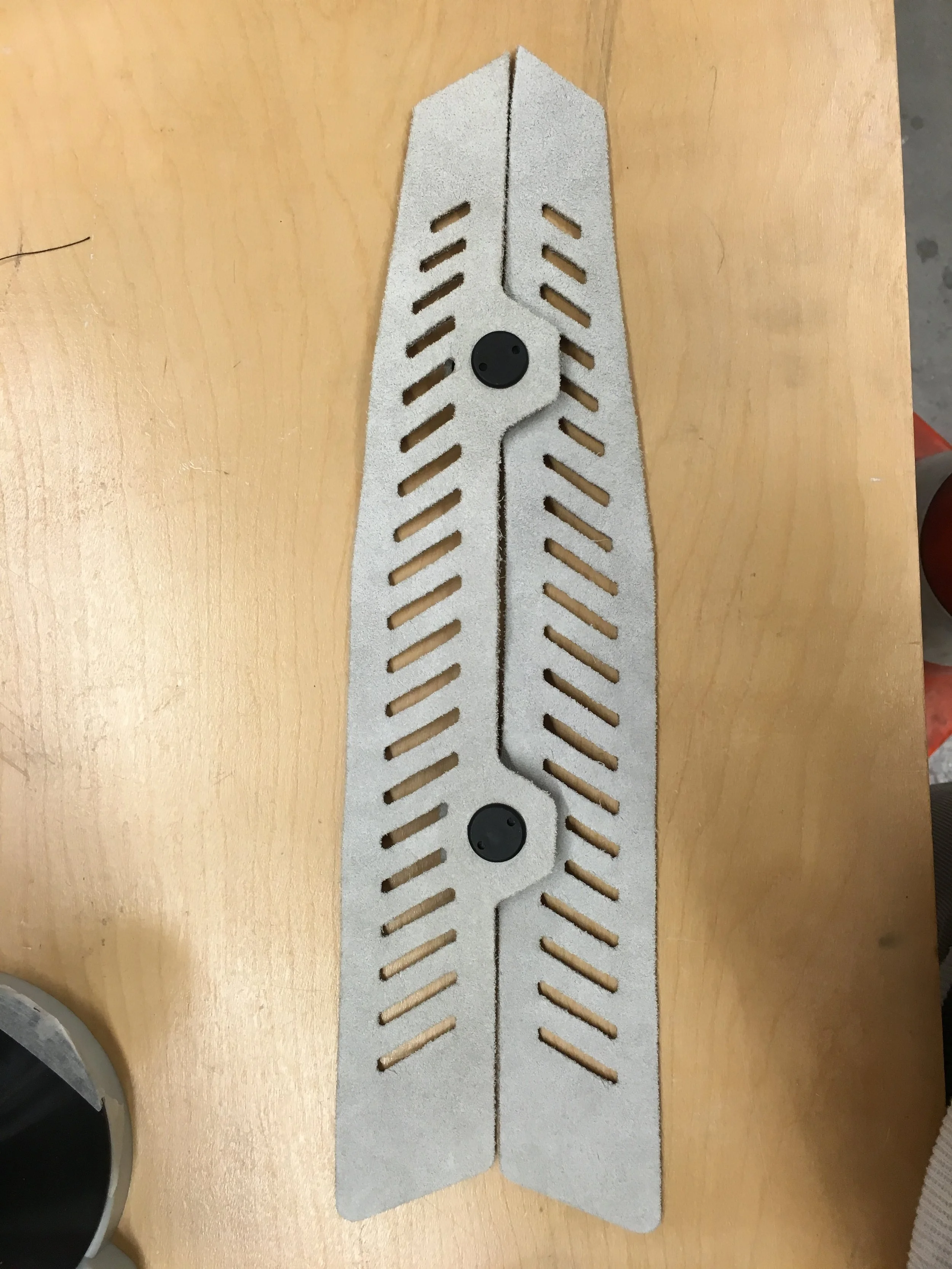

Many of the innovations featured in these prototypes stem directly from my own dedicated research and development efforts, showcasing a commitment to pushing the boundaries of what is possible in softgoods design. For instance, I have perfected an intricate method for laser-cutting leather suede that avoids burning or discoloration, thus preserving the material’s natural integrity, texture, and aesthetic appeal. I’ve also introduced an eco-friendly, non-toxic fabric (originally developed for use in lunch bags), as a waterproof liner in travel bags, effectively enhancing sustainability measures without compromising durability or performance. Furthermore, the integration of newly released Fidlock magnetic snaps facilitates a transformative modularity in backpack straps, enabling them to seamlessly join together into a single strap, which fundamentally alters the orientation, comfort, and functionality of the bag in practical, innovative ways.

Each project begins with a conceptual sketch that is then carefully refined through detailed CAD modeling and numerous iterative adaptations. By managing every phase of the production process, from initial drafting and precision cutting to expert sewing and final finishing. I retain unparalleled control over the design’s evolution. This comprehensive oversight allows for deep insights to inform each design decision, ensuring that the final product is not only aesthetically balanced but also highly functional and technically advanced. This lean and agile approach empowers my studio to rapidly translate innovative concepts into fully realized, shelf-ready products, often positioning us ahead of broader industry trends. Notably, we were among the first in the United States to market products featuring Fidlock technology and were early adopters of laser-cut leather techniques, consistently setting a precedent for technical excellence and innovation within the realm of softgoods design.